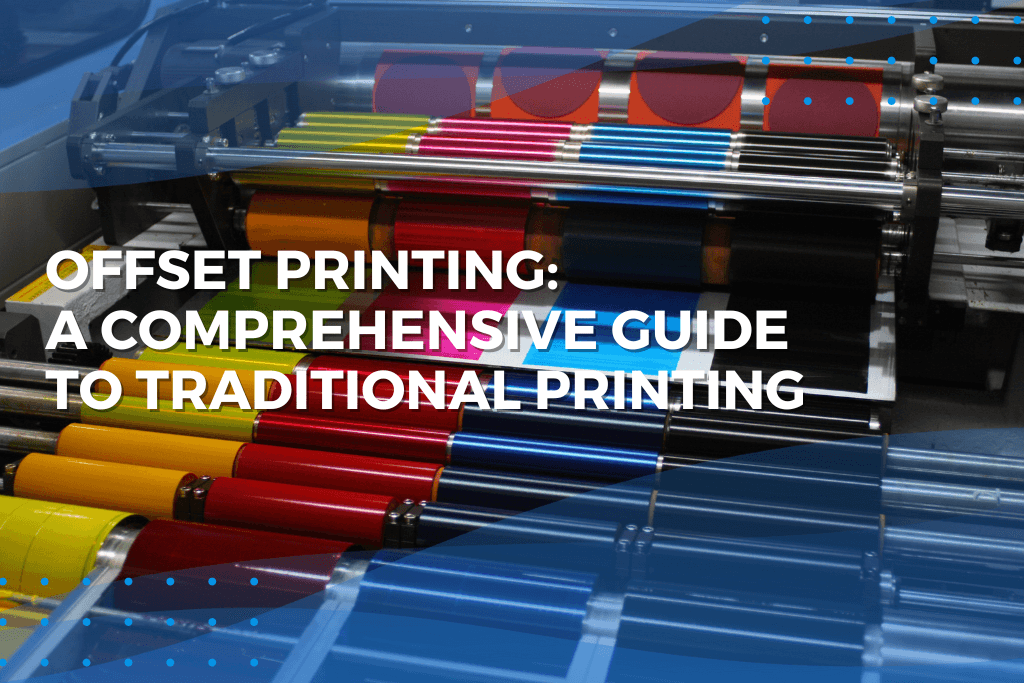

Offset printing has been the backbone of the printing industry for over a century. It remains one of the most common methods used for large quantity print jobs, as it continues to ensure consistent quality and cost-effectiveness. In this all-inclusive guide, we’ll explore the inner workings of offset printing: its history, its mechanics, advantages, disadvantages, and applications in today’s digital landscape.

What is Offset Printing?

Offsetting printing also known as offset lithography is a printing technique where an inked image is transferred, or “offset,” from a plate to a rubber blanket and then to the printing surface. The offsetting technique employs a flat (planographic) image carrier on which the image to be printed gathers ink through rollers, while the non-printing area receives a water-based film called “fountain solution” that keeps the non-printing areas ink-free.

A Very Brief History of Offset Printing

Offset printing actually has its roots in an 1875 UK patent that Robert Barclay submitted for an offset press to print tin plates. The actual modern offset process, however, was invented independently by two different inventors.

In 1903, Ira Washington Rubel stumbled across the basic principle of offset printing when operating his American paper mill. He takes notice that when a rubber cylinder fails to pick up paper for printing, it leaves a clearer image on the next sheet. This becomes the starting point for developing the first offset printing press for paper.

Around the same time, Caspar Hermann in Germany started working on the similar concept. He managed to produce an offset press and started manufacturing it in 1907. All these early inventions led to offset printing becoming the prime form of commercial printing in the 20th century.

How Offset Printing Works

The offset printing process involves a number of key components and steps:

- Plates: The image to be printed is transferred onto thin metal plates, generally aluminium. Every colour of a print job requires a separate plate.

- Inking System: The plates mounted on plate cylinders in the press rotate, coming into contact with rollers that apply ink and water to them. Water will stick to the non-image areas, whereas the oil-based ink will stick to the image areas.

- Offset Cylinder: The inked image from the plates onto a rubber blanket wrapped around another cylinder. It’s an intermediate step, that’s why it’s called “offset” – the image isn’t printed directly from the plates to the paper.

- Impression Cylinder: The paper runs through the press and is placed against the rubber blanket by the impression cylinder, which transfers the image onto the paper.

- Drying: The printed sheet is then passed through a drying system, depending on the ink used, such as heat, infrared, or UV curing.

For four-colour prints, this cycle repeats once for cyan, magenta, yellow, and black, respectively, commonly referred to as CMYK. The exact combination of these colours makes the full-colour image.

Advantages of Offset Printing

High Image Quality: For that matter, images and type in offset printing tend to be sharper and cleaner because the rubber blanket morphs to the texture of the printing surface.

Cost-Effective for Large Runs: Although the set-up charges can run rather steep, offset printing saves a lot of money with large quantities, thereby suitable for more substantial print runs.

Variety of Materials: Offset presses can print on all types of paper, and any size, and also on wood, cloth, metal, plastic, and much more.

Colour Accuracy: Offset printing provides excellent colour control and consistency-a critical factor in brand identity and high-quality art reproduction

Plate Longevity: The offset printing plates can produce numerous impressions before having to be replaced.

Use special custom-mixed inks: Pantone colours, metallic and fluorescent are only possible on an offset.

Applications of Offset Printing

Offset printing is used to print numerous items, including:

- Newspapers and Magazines: Mass market periodicals are typically printed on web offset presses that print to large rolls of paper.

- Books: Many hardcover and paperback books are offset printed.

- Brochures and Catalogues: Offset provides the best print quality for volumes and inexpensive for large orders, making it the best option for printing marketing products.

- Packaging: From food packaging to product boxes, offset printing has been employed in various packaging.

- Stationery: Since most of the business cards, letterheads, and compliment slips are offset printed.

- Posters and Art Prints: Colour accuracy makes offset the most favourite among artists.

Offset vs. Digital Printing

Offset printing has been the darling of the industry for decades, but digital printing comes with the strength of smaller runs. Compare:

- Setup Time and Cost: Digital printing requires less setup and hence cheaper for small quantities. Offset has higher setup but gets cheaper as the number increases.

- Print Quality: Offset is more likely to produce higher quality prints, with more smooth colour gradations. Notwithstanding this, digital printing has really improved on its print quality.

- Customisation: This is the area where digital printing shines. Variable data printing and personalisation require less flexibility from the offset counterpart.

- Colour Accuracy: The colour control is better on offset printing and incorporates special inks rather easily.

- Paper Options: More numerous paper stock and materials can be printed on using an offset printer.

- Turnaround Time: The turnaround of digital printing is relatively faster, especially when the job is small.

Environmental Concerns

Printers have long been criticised about environmental issues. In fact, offset printing has faced a lot as well. There have been several developments that make this type of printing more environmentally friendly:

- Vegetable-based inks: Most printers now use vegetable-based ink instead of petroleum-based ink, thus reducing VOC emissions and easier recycling.

- Alcohol-Free Printing: Some printers have given up the fountain solution from containing isopropyl alcohol, which decreases the exhaust of air pollutants.

- Computer-to-Plate (CTP) Technology: This simply means that plate making involves using digital data to print the images on the plate itself; no more chemical-intensive film required.

- Paper Options: Using recycled paper or paper from responsibly managed forests has become a growing option.

- Reduce Paper Waste: Technological advancements and changed methods in setting up and production minimise scraps of paper for disposal.

Off-Set Printing in the Future

Whereas digital printing and online media cover the globe’s surface with communications, offset is still a cornerstone of today’s printing industry. Its potential future rests on meeting changing market needs and technological developments:

Hybrid Printing: A few are already combining elements of offset and digital, allowing offset to do offset and digital to do digital in one print run.

Automation: Automation of plate making, press setting, and quality control reduces waste better and allows for faster setup.

UV and LED Curing: Their advantage is that they allow faster drying times and can be printed on a wider range of materials.

Improved Inks: Sooner rather than later, the ongoing developments in ink technology are improving print quality and the environment friendliness.

Offset printing is integrated into digital workflows, thus offset printing reduces the complexity of production processes.

Conclusion

With such an age-old history and proven track record, offset printing is, without an iota of doubt, a very vital aspect of the printing industry. The ability to produce high-quality prints cost effectively and in quantities that have, over the years, even eclipsed what was considered large ensures it a very significant place in the digital world. How well this technology evolves, solves some of the environmental concerns, and integrates with digital workflows will do wonders for offset printing in yet more changes in business and consumer requirements.

Whether you are a business owner interested in your options for printing, a graphic design student who would love to know more about production processes, or just someone who’s just plain curious about the complex processes that bring magazines and books into your hands, understanding how offset printing works really gives you a lot of insight into one of the most fundamental aspects of our visual culture. And going forward, of course, offset printing will do its part to adapt and to evolve to ensure that it remains a cornerstone of the printing industry.

Need High-Quality Printing for Your Business?

Contact us today to learn more about our offset printing services and how we can help you achieve stunning results.